In July 2023, China announced export licensing for gallium and germanium, sharply restricting flows and creating immediate friction across global supply chains. Spot prices for gallium spiked by more than 40 percent in Europe, leading to longer lead times andforcing chip fabs to draw down inventories and prioritize critical programs. Shipments could not leave China until licenses were approved, forcing sellers to wait, and some buyers to tap into stockpiles.

This event rattled more than just commodity markets; it exposed a fault line in the US defense industrial base.

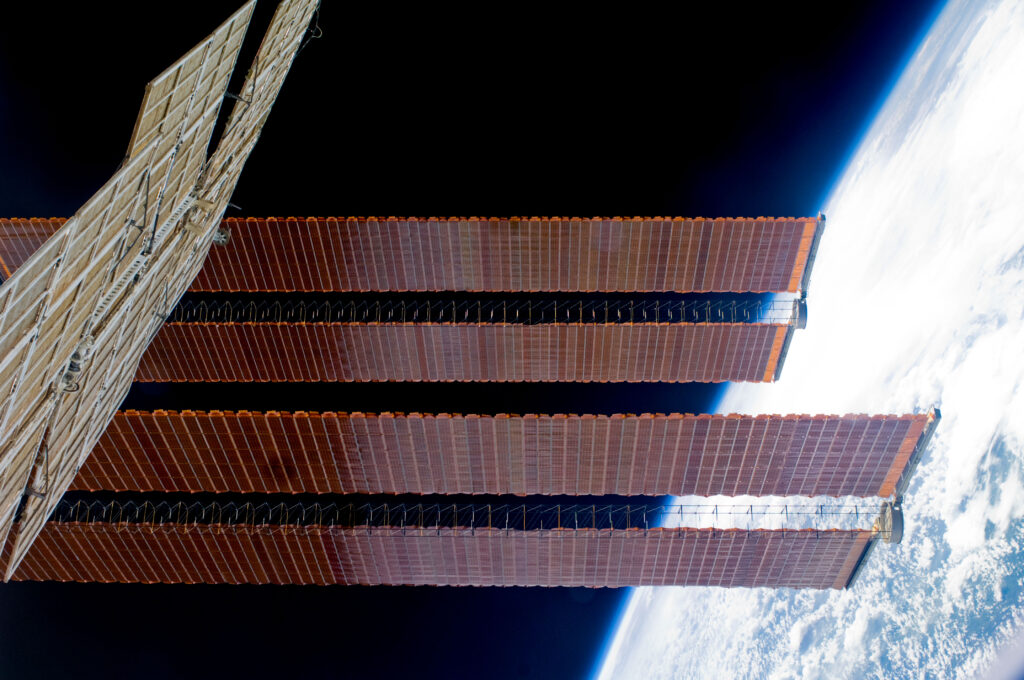

Gallium has an outsized yet overlooked strategic value. Embedded in radars, missile seekers, secure radio frequency links, and satellite solar cells, this obscure metal is crucial for advanced electronic warfare systems. The United States produces no domestic gallium and lacks a government stockpile to cushion against Chinese weaponization.

This is the gallium dilemma: a small metal with huge consequences for US war readiness. Solving it does not mean new mines or scouring the globe for deposits. Instead, the United States must proactively recover gallium already flowing through the domestic industrial system—before it slips away as waste.

Gallium’s strategic stakes

Gallium is not a bulk commodity like copper or steel. The United States consumes only about 20 tons per year, enough to fit on a single flatbed truck. Yet that small volume anchors the entire US defense industrial base. Gallium is critical for the electronics supply chain and is needed for many advanced US weapon systems and satellites.

The irony is that gallium is both everywhere and nowhere. It exists in trace amounts in US ores processed daily, such as alumina, zinc, and coal residues. However, without a deliberate recovery strategy, gallium vanishes into waste products. China commands nearly 99 percent of primary output not because it discovered richer deposits, but because Beijing made the choice decades ago to recover gallium during aluminum production.

Export limitations should be treated as an opportunity to act before the next crisis. If an adversary can weaponize a couple dozen tons of gallium, then the United States’ economic, military, and technological edge is more at risk than most policymakers realize.

The supply dilemma

The United States cannot mine its way out of the gallium dilemma. Gallium rarely concentrates beyond a few parts per million, substituting invisibly into aluminum and zinc ores. Unlike lithium or copper, no ore deposit has been discovered in high enough grades to anchor a mine. The one historical exception was the Apex Mine in Utah, reopened in the 1980s to extract gallium and germanium from a uniquely enriched deposit. It shuttered within two years due to dipping commodity prices, ore quality issues, and costly metallurgy. Apex showed that primary gallium mining is not sustainable.

Apex’s closure left the United States wholly dependent on imports. Today, nearly all low-purity gallium originates in China, and only a single facility in New York upgrades imported feedstock and semiconductor scrap into high-purity metal. It is a critical capability, but far too limited to insulate war materiel supply chains from shocks. When China imposed export licenses, US buyers had no fallback beyond drawing down what little stock they held.

Other countries manage the risk differently. Japan and South Korea maintain government reserves of gallium as part of their broader critical minerals strategies. China is widely believed to hold state stockpiles, although quantities remain undisclosed. The United States, by contrast, does not include gallium in the Defense Logistics Agency’s Annual Materials Plan, nor is it present in the National Defense Stockpile.

Gallium is abundant in theory but inaccessible in practice. Every ton of alumina or zinc refined in the United States carries trace gallium. Capturing just 1 percent of that byproduct could meet US demand. But without dedicated recovery units, gallium disappears into red mud, slags, or smoke stacks.

US gallium security will not come from new mines; it requires policy choices that treat trace gallium recovery as seriously as any weapons program, especially before the next supply shock strikes.

From trash to treasure

The only path forward is to capture gallium where it already flows: existing industrial processes. A “waste to gallium” approach leverages infrastructure that already processes millions of tons of alumina, zinc, coal residues, and semiconductor scrap. The chemistry is proven. Now Washington must encourage industry to scale, qualify, and sustain output at the purity military materiel requires.

There are five ways for the United States to increase domestic supplies of gallium.

First, alumina refining offers the quickest way to increase the gallium stockpile. In aluminum production, most of the gallium dissolves into the caustic liquor, with the rest bound up in red mud waste. China’s decision to install capture units turned its aluminum refineries into a strategic asset. The United States has no such capacity today, though pilots are emerging. ElementUS, for instance, has 30 million tons of red mud in Louisiana and is testing flowsheets that recover gallium alongside iron, alumina, and scandium. The project underscores that, while gallium recovery rarely makes economic sense alone, it can be viable when folded into multiproduct strategies.

Second, zinc smelters can diversify sources and methods for gallium extraction, improving supply chain resilience. Gallium tends to concentrate in residues like jarosite and goethite, which can be leached and refined. Nyrstar, operating a major facility in Tennessee, has floated plans for a gallium-germanium recovery circuit capable of covering a significant share of US demand. The chemistry process is relatively straightforward and validated by National Laboratory tests, but financing remains elusive. Without targeted support, promising projects like this will never leave the drawing board.

Third, there is a need to secure gallium supplies through allies and partners. In 2025, Rio Tinto and Indium Corporation demonstrated gallium recovery at the Vaudreuil alumina refinery in Quebec, with pilot steps carried out in New York. European pilots like RemovAL are testing red mud leaching, while Japan and South Korea are investing in recovery processes. The pattern is unmistakable; countries that anticipate future scarcity are embedding gallium capture into their industrial ecosystems. US policymakers should encourage gallium recovery integration with allies and partners to maximize options.

Fourth, coal-based waste offers another gallium capture option. Fly ash and acid-mine drainage contain low concentrations of gallium. The Department of Energy has piloted mild-acid leach processes originally designed for rare earth elements that can be adapted to recover gallium. The economics depend on co-recovering other critical minerals, but the prospect of transforming waste piles into strategic feedstock shows the versatility of the approach.

Finally, the most overlooked—yet easiest—gallium recovery pathway is semiconductor scrap. A single US refiner in New York already upgrades scrap into high-purity gallium. While modest in scale, this capability provides military-grade material through shorter supply chains and clear traceability—advantageous for defense buyers who need secure, auditable sources. The United States should seek to increase the number of refineries recycling semiconductor scrap to build a high-purity gallium stockpile.

Three policy levelers for US gallium security

Recovering gallium from waste streams is not a scientific gamble; this chemistry has been proven for decades. What is needed are deliberate policy decisions to turn waste into war-ready gallium. Achieving this will require US financing, qualification, and stockpiling. Absent these choices, America’s industrial base will remain exposed to Beijing’s weaponization.

The first priority is qualification-first funding. For military applications, purity and delivery cadence matter as much as volume. Producing a few kilograms in a lab means little if the material cannot sustain continuous production at 99.999 percent purity or higher. The Department of Energy’s TRACE-Ga initiative, which requires 50 kilograms from a fourteen-day continuous run, is a step in the right direction. This model should be expanded, with defense agencies directly engaged to ensure outputs meet actual military needs.

The second lever is de-risking first-of-a-kind flowsheets. Banks rarely finance recovery circuits that have never operated at scale in the United States. Federal tools can fill the gap, including Loan Programs Office guarantees, cost-sharing through the Office of Clean Energy Demonstrations, and Defense Production Act offtake agreements calibrated in kilograms per month, not speculative tons per year. The Department of Energy has signaled nearly $1 billion in forthcoming funding opportunities across critical minerals, including byproduct recovery and processing. Targeted commitments would give investors confidence while avoiding stranded capacity.

Finally, Washington must establish a modest gallium stockpile. A reserve of at least 1,000 kilograms would buy time during licensing delays or supply shocks. Japan and South Korea already follow this gallium stockpiling playbook; the United States must now do the same.

As strategic competition deepens and global supply chains decouple, national power will hinge on securing the chemicals and materials that keep modern economies and militaries running. China’s export restrictions are a reminder that military success can depend on just a few kilograms of gallium. If Washington lets gallium slip into its waste streams, this hands Beijing more leverage.

The choice is clear. America must turn trash into treasure—or let rivals weaponize scarcity.

Macdonald Amoah is a communications associate at the Payne Institute for Public Policy where he conducts research on topics bordering on critical minerals and general mining issues.

Morgan D. Bazilian is the director of the Payne Institute for Public Policy and professor at the Colorado School of Mines. Previously, he was lead energy specialist at the World Bank and has over two decades of experience in energy security, natural resources, national security, energy poverty, and international affairs.

Lt. Col. Jahara “FRANKY” Matisek is a US Air Force command pilot, nonresident research fellow at the US Naval War College and the Payne Institute for Public Policy, and a visiting scholar at Northwestern University. He has published over one hundred articles on strategy and warfare.

Col. Katrina Schweiker is a US Air Force physicist and military fellow with the Defense and Security Department at the Center for Strategic and International Studies. She has spent a decade working at the intersection of science and technology and military strategy.

The views expressed are those of the authors and do not reflect the official position of the US Naval War College, US Air Force, or Department of Defense.

stay connected

Sign up for PowerPlay, the Atlantic Council’s bimonthly newsletter keeping you up to date on all facets of the energy transition

related content

our work

The Global Energy Center develops and promotes pragmatic and nonpartisan policy solutions designed to advance global energy security, enhance economic opportunity, and accelerate pathways to net-zero emissions.

Image: Starboard Solar Array Wings (NASA, https://images.nasa.gov/details/iss018e042659)