3D printing (additive manufacturing) has been around for nearly three decades, but only in the last few years has it captured the imagination of millions of people with its potential to manufacture almost any object, as well as to create complex objects impossible to make via traditional manufacturing approaches. Three years ago, the Atlantic Council explored the implications of 3D printing in a groundbreaking report, Could 3D Printing Change the World?

A new report by Thomas A. Campbell, Skylar Tibbits, and Banning Garrett, The Next Wave: 4D Printing – Programming the Material World, examines 4D printing, a new disruptive technology on the horizon that may take 3D printing to an entirely new level of capability with profound implications for society, the economy, and the global operating environment of governments and businesses alike. Programmable Matter (PM), here described as 4D Printing (4DP), has the economic, environmental, geopolitical, and strategic implications of 3D printing, while providing new and unprecedented capabilities in transforming digital information of the virtual world into physical objects of the material world.

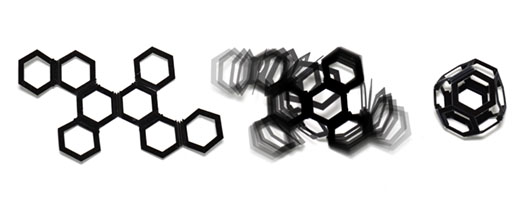

The fourth dimension in 4D printing refers to the ability for material objects to change form and function after they are produced, thereby providing additional capabilities and performance-driven applications. Imagine a world in which solid material objects can morph into new shapes or change properties at the command of an individual or in pre-programmed response to changing external conditions like temperature, pressure, wind, or rain. That world is on the horizon.

This report presents the latest results on 4D printing and programmable matter to offer context for this potentially world-changing technology. Examples of 4D printing are printed objects that can change shape when inserted in water or exposed to electricity and 3D printed sensors with embedded nanomaterials that change color when exposed to different light sources. Applications could include morphable building materials and sportswear, tires that transform for adaptive grip, and infrastructure/pipes controlling flow/pressure. Introducing programmable capabilities into 3D-printed materials could enable robot-like capabilities embedded directly into the materials, without the need for energy-intensive and failure-prone electro-mechanical devices.

Programmable matter and 4D printing certainly have the potential to appear “magical,” but they are grounded in real engineering and science research that is only now emerging due to recent technological advances. Through programmable matter and 4D printing, there exists the potential to create a new class of disruptive technologies for the benefit of humanity.